Fantastic enzymes: where and how to find them

This post has been jointly written by Patricia Molina Espeja, Markus Müller, Sara Daniotti, Manuel Ferrer, & the FuturEnzyme Consortium.

Enzymes are everywhere. Wherever you look in a living organism, there they are. Inside yourself exist at least 4000 different enzymes (proteins with catalytic activity) carrying out substantial reactions that allow you to breathe, to be nourished, to obtain energy, to run, to think… It is estimated that all over the globe live more than 1012 different microbial species. This number is more than 100-fold higher than the current world population. Altogether, microbial species contain 1010 to 1015 different enzymes, but only 0.0001% of them have been recovered. Imagine the possibilities! Currently, enzymes are used in a multitude of sectors, including automotive sector (e.g., car-body parts), building industry (e.g., bio-based concrete admixtures), mechanical engineering sector (e.g., bio-lubricants), energy sector (e.g., biogas), chemical and pharmaceutical sectors (e.g., bio-based platform chemicals), agriculture and forestry sector (e.g., plant and animal breeding), food and beverage industry (e.g., enzyme-processed foods and drinks), consumer goods (bio-based cleaning and cosmetic agents), and textiles and clothing (e.g., bio-processed fabrics). The molecular understanding of the highly specific catalytic enzyme activity has increased in the last years, but many questions on the underlying mechanisms and biochemical reactions remain unknown. Therefore, we are way too far from easily discovering the perfect enzyme for every use we envision.

Searching for enzymes

Natural enzymes are fantastic in their original environment: nature has constantly evolved their sequences and thus their characteristics for more than 3.4 billion years. But using them outside their original purpose… this is quite a challenge! Consider, for example, that the enzymes that are used with liquid laundry detergents have to be stable in complex formulations of many chemicals for months or years and at very different storage temperatures; at the same time, they should have a high stain removal capacity when added in the washing machine under different washing programmes. In the textile sector, enzymes are needed, for example, to assist with the removal of chemicals during production, that otherwise need to be pulled out of the fabrics using excessive amounts of hot water.

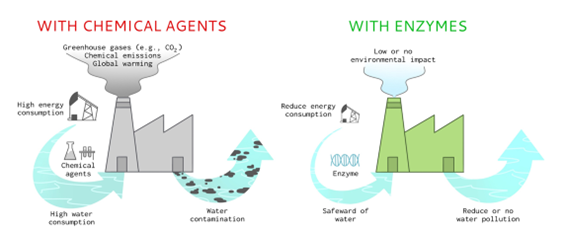

However, enzymes in nature are rarely adapted to these synthetic chemicals, and finding any enzyme capable of being stable in, or active against, them is rare. The hyaluronic acid-based cosmetics industry needs enzymes able to hydrolyse this large polymer into fragments of a particular size to provide the best anti-ageing properties; enzymes existing in nature are capable of cutting this polymer but unfortunately only into very short fragments which are not compatible with the requirements of the industry. What makes enzymes so valuable for these and other uses is the combination of their huge applicability and optimisation potential with their green performance. By including enzymes in any process, the negative impact on the environment is mostly lowered (or even eliminated), since chemicals usage is reduced, energy and water consumption is lessened, and cleaner wastewater is released (Figure 1).

To find innovative and game-changing biocatalysts that meet industrial requirements, we are now able to bio-prospect our planet in search for the best hits, even in extreme (e.g., salt seas, volcanos) or rare (e.g., long-term abandoned sofas in landfills) environments. In addition, we can perform DNA sequencing better, faster and cheaper and to generate extraordinary vast amounts of sequences that are sources of enzymes. Theoretically, we can come up with sequences of all the enzymes that the microbes inhabiting our planet have to offer (1010 to 1015). But finding among them the enzyme that fits our needs is impossible by manual testing. Artificial intelligence and computational methods have given us the opportunity to screen large enzyme libraries for candidates and to make further precise and directed modifications to their sequences and structures (mutations). In this way, a target enzyme can be identified and its activity can be adapted to a specific aim and to the intended characteristics. Optimising the underlying algorithms, machine learning and enzyme engineering can feed each other for better results, while speeding up and reducing the cost of producing the desired enzymes.

Working with industry to optimise products and processes

In FuturEnzyme, we take advantage of decades of expertise in these fields, combined with expertise in microbiology, enzymology, molecular biology, bioprocessing, and others, to track down enzymes that can be used in, at least, three significant sectors: detergents, textiles and cosmetics. These are consumer products that are used every day, in which enzymes can provide significant benefits and increase sustainability, as will be detailed below. The idea is not to produce new such products but to improve, with the use of new enzymes, already existing ones or the production chains for their bioprocessing, thereby providing environmental and economic benefits over their whole life cycle. These benefits cannot be addressed if industrial enzyme production is not economically feasible and does not follow appropriate techno-economic parameters. Thus, detergents, which cost less than €5 per kilo, require enzymes whose production cost should not exceed €0.1-10 per kilo, and cosmetics and textiles, costing more than €5 per kilo, require enzymes with production costs of up to €100 per kilo.

The methodology developed by FuturEnzyme includes a precise knowledge of the needs of the manufacturers implied in the project. Starting with miniaturised tests in which these conditions and needs are evaluated, this knowledge helps to develop the targeted products in more eco-healthy, sustainable and innovative ways. Moreover, understanding the industry needs helps to develop experimental and computational tools to identify and optimise enzymes that meet specific industry requirements at an adequate level. We intend to identify at least a hundred enzymes out of the millions we have access to. Subsequently, the most promising candidates will be tuned by means of novel engineering techniques at genetic and supramolecular levels. At larger scale, the highest enzyme performances and production yields are aimed to reduce the cost of enzyme use in innovative industrial value chains.

Relevance to the consumer

The three sectors that are the focus for FuturEnzyme have been selected for their relevance as daily-use consumers’ products, for which a 4.8-6.3% of annual growth consumption rate is estimated. Our three industrial partners (Henkel, Evonik and Schoeller) have been committed to eco-production for decades by implementing innovative solutions all along their products’ value chain. Within FuturEnzyme, we aim at levelling-up their sustainability potential.

Laundry detergents can be “greened” by including enzymes into the formulation that allow for colder washing temperature. At lower temperatures, enzyme use shows the potential to maintain or even increase the washing efficiency. This results in lower consumption of energy, chemicals and water, while releasing cleaner wastewater. Keep in mind that a standard washing programme with a most efficient enzymatic detergent will allow you to wash your clothes at 30°C and annually save 30% energy compared to a 40°C wash cycle, plus reduce the CO2 emission equivalent to a gasoline-powered passenger vehicle driven for one year.

In the case of cosmetics, we focus on the enzymatic production of a hyaluronic acid molecule to be included in skin care products; a hyaluronic acid polymer of a defined size, produced on the basis of eco-friendly parameters, makes it possible to have a product with improved anti-ageing and skin tolerance properties.

For textiles, the implications are manifold. One of the problems in the textile industry is the excessive use of water and energy. At least seven treatment steps are necessary to produce fabrics out of an initial fibre, including various washing and dyeing steps. Enzymes can decrease water and energy consumption by efficiently removing chemicals (e.g. silicon/mineral oils, excess dyestuff). Consider that the use of enzymes for chemicals clean-up can save 1000 kg CO2 and 20000 liters of water per tonne of yarn. Enzymes can also play a key role in the degradation of textiles at the end-of-life, thus enabling circularity and efficient recycling of used textiles. Remember that if we recycled textiles with enzymes, we would save CO2 equivalent to 1 car on gasoline driving two and a half years, and 234000 liters of water consumption per tonne of textile input compared to the chemical processes; as well, this can prevent our planet accumulating 3400 megatonnes of clothes waste by 2030.

In the process of searching for optimal enzymes to be applied in these specific sectors, it may happen that many enzymes do not meet the target specifications, but have valuable properties for other sectors. Examining this potential is a further priority of the project. Therefore, in addition to the three target sectors, FuturEnzyme’s fantastic enzymes will as well cover other processes or products that seek eco-excellence. Our general aim is to provide a collection of biocatalysts with high capacities, independently of the targeted application. In addition, with all the knowledge acquired along the project plus the partners’ broad experience, we aim to develop a predictive software that enables an accurate and purpose-based targeted selection of enzyme candidates in sequence repositories. This will provide a significant milestone in the field of enzyme discovery, as the conventional process is labor-, cost- and time-consuming.

Enzymes for a circular and sustainable bioeconomy

The protection of the environment is a must for FuturEnzyme, and so we are willing to contribute to the objectives of a circular and sustainable bioeconomy, being formulated by the Paris Climate Conference (to reduce greenhouse emissions by 55 gigatonnes of CO2 equivalents in 2030, which corresponds to the amount of CO2 that can be captured by all the trees growing in Europe over ten centuries), the European Green Deal (become the world’s first climate-neutral continent by 2050 while improving economic competitiveness), the Recovery and Resilience Plan (to rebuild a post-COVID-19 Europe), and the United Nations’ Sustainable Development Goals (implications in 12 out of the 17 SDGs). According to the International Panel for Climate Change (IPCC), we are still in time to revert global warming, but not for long, and it will be more complicated as it keeps increasing. Every action counts, and enzymes can count a great deal!

The FuturEnzyme project is funded by the European Union’s Horizon 2020 Research and Innovation Programme under Grant agreement no 101000327.

Top image by FuturEnzyme

Join the FEBS Network today

Joining the FEBS Network’s molecular life sciences community enables you to access special content on the site, present your profile, 'follow' contributors, 'comment' on and 'like' content, post your own content, and set up a tailored email digest for updates.